Components for intermodal transports

General information

Special versions

Telescopic part

Struts

Outer bearing

Second safety device

Support bearing

Information plates

Corner castings

General informations

For freight containers that comply with ISO 1161–1984

For swap bodies with a vehicle width of 2500 mm

For swap bodies with a vehicle width of 2550 mm

For intermodal platforms with a vehicle width of 2500 mm

For intermodal platforms with a vehicle width of 2550 mm

For stackable swap body conforming to EN 13853

For special constructions

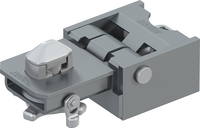

Twist locks

General informations

Installation examples

FD 02 SK-RV

F 02 SK-R

R 402 F-R / R 302 F-R

R 403 FR / R 403 FL

R 402 FQ-R

R 414 F / R 314 F

R 434 F / R 334 F

R 408 F / R 308 F

F 17 SKA-70 V

F 10 SK-RV

R 401 VAK / R 301 VA

VA 01 SK

R 316 VAP

R 406 VAK / 306 VA / 406 VAK-C / 405 VAK / 305 VA / 405 VAKR

R 405 VAN / R 305 VAN

R 305 VAP

R 416 VAK / R 316 VA

R 436 VAK / R 336 VA

R 1018

TL 2009

QA 37 NS

QA 38 NS

VA 11 SK

FB 55 HL

FB 88 – 14 V

FB 90 – 06 VA

FB 90 F

FB 91 NS

HV 120V

HVC with locking kit

HV with locking kit – Easy Lift (force-assisted)

R 316 ZWEI

Locking pin with thread limited by a ring

Locking pin with thread limited by a toggle

Guide bush

Outer bush

Locking nut

Security latch with a short and a long front latch

Security latch standard

Ball lock

Anti-theft lock DS 300

Spanner for twist locks

Installation tool

Airbag lifting device

General informations

Actuating system 1 HS and 2 HS

HS 5000 / 8000 / 10000 EO

HS 8000 EON

HS 8000 / 10000 ES

HS 5000 / 8000 ESN

HS 8000 ESN 04

HS 8300 ES-W1

Guide roller, side

Lifting bellow

Bead ring

Guide rollers

Folding pin 000.008.008

Guide roller bearings 650.002.019 + 650.002.039

Guide roller bearings 650.002.055